How to Build a Solar Dehydrator

As someone who enjoys preserving food naturally, I’ve always been intrigued by solar dehydrators. Solar dehydrators are an eco-friendly and energy-efficient way to dry food, such as fruits, vegetables, and herbs, using the power of the sun. By understanding the basics of solar dehydration and the types of solar dehydrators available, anyone can create their own device to enjoy the benefits of sun-dried food.

Building a solar dehydrator might seem like a daunting task, but with the right materials, tools, and a solid understanding of the components, it’s possible to construct a small or large dehydrator. Safety is key when working with solar power, so it’s essential to keep some tips and reminders in mind as you embark on this project. Additionally, knowing where to find additional resources and answers to frequently asked questions can help ensure a successful solar dehydration experience.

Key Takeaways

- Solar dehydrators provide an eco-friendly method for drying food using sunlight

- Constructing a solar dehydrator requires understanding components and gathering appropriate materials

- Safety and finding additional resources are essential for a successful solar dehydration experience

Understanding Solar Dehydration

Solar dehydration is a method that harnesses the sun’s power to dry and preserve food. Dehydrated foods have a lower moisture content, making them shelf-stable and lightweight. They also retain most of their nutritional properties and health benefits compared to fresh food.

I first learned about the solar drying process when I stumbled upon Oklahoma State University’s Solar Dehydrator Construction Plans. It became clear to me that solar energy has the potential to provide a sustainable and energy-efficient way to preserve food without relying on electricity. The process involves the use of a solar dehydrator which collects energy from the sun to heat air that is then used to dehydrate food and agricultural products.

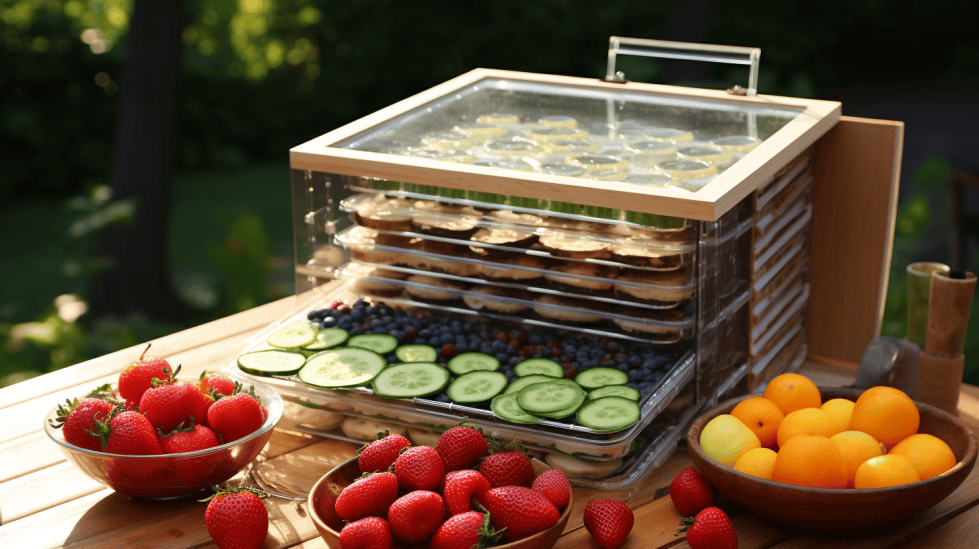

Building a solar dehydrator involves the construction of two main components: a heat collector and a dehydrator box. The heat collector has a clear plastic top that heats up and pushes the warmed air into the dehydrator box above it. Controlling the airflow and temperature is done by adjusting vents at the bottom of the dehydrator. Food is then stored on screen trays within the dehydrator box where the hot air circulates, gradually removing moisture.

When I use solar dehydration, it is vital to ensure that my dehydrator is positioned to receive maximum sun exposure, which typically means facing south in the Northern Hemisphere. Placing the dehydrator on a stable surface and ensuring proper ventilation help improve the efficiency of the drying process as well. It is also essential to monitor the food being dried regularly to prevent over-drying or spoilage.

In conclusion, solar dehydration is an eco-friendly, cost-effective method for food preservation that takes full advantage of the sun’s power. By understanding the principles behind solar energy and the dehydration process, it becomes a practical alternative for those interested in producing dehydrated foods in a sustainable manner.

Types of Solar Dehydrators

Passive Solar Dehydrator

A passive solar dehydrator is a type of solar dryer that relies solely on the sun’s energy to dry food. This method doesn’t use any external power sources or fans, making it an eco-friendly and cost-effective solution. The basic design of a passive solar dehydrator includes a heat collector and a drying box or chamber. The heat collector, usually built with a clear plastic top, captures and retains the sun’s energy, causing the air inside the collector to heat up and rise. This hot air then enters the dehydrator box, where it dries the food. I found some DIY solar food dehydrator plans that you might find helpful if you’re looking to build one of your own.

When planning your solar dehydrator construction, you’ll want to consider factors such as:

- Size: The size of the dehydrator will determine how much food you can dry at one time. Keep in mind your available space and expected usage.

- Materials: Choose durable, weather-resistant materials for a long-lasting dehydrator.

- Ventilation: Proper air circulation is essential. Make sure your design includes vent holes or an adjustable vent system to regulate airflow.

Active Solar Dehydrator

An active solar dehydrator, on the other hand, integrates additional devices like solar panels and fans to improve the drying process. By using solar energy to power fans, the dehydrator can circulate the heated air more efficiently, resulting in faster drying times and better food quality. An active solar dehydrator might be the best means for those who live in areas with less consistent sunlight or who want to maximize the efficiency of their solar food dryer.

When constructing an active solar dehydrator, consider the following aspects:

- Solar panels: Look for solar panels with adequate output to power the fans and other electrical components in the dehydrator system.

- Fans: Choose energy-efficient fans to optimize air circulation and minimize energy consumption.

- Temperature control: Some active solar dehydrators include thermostats or temperature sensors to help maintain consistent heat levels and prevent over-drying.

In summary, both passive and active solar dehydrators offer environmentally friendly solutions for food preservation. Based on your location, budget, and drying preferences, you can choose the solar dehydrator construction plan that best suits your needs. Happy building!

Components of a Solar Dehydrator

Solar Collector

The solar collector is responsible for converting sunlight into heat. It is typically made from materials like plywood and has a clear plastic or polycarbonate top. I need to paint the inside of the solar collector with a matte black paint to increase the absorption of sunlight and help generate heat. The solar collector should be placed at an angle to maximize exposure to sunlight. This ensures efficient energy conversion and proper airflow throughout the dehydrator.

Drying Chamber

As the name suggests, the drying chamber is where the actual dehydration process takes place. It is usually built above the solar collector and can be made from plywood, screen mesh, and plexiglass. The front of the drying chamber should be clear to let sunlight in and provide visibility to the contents. It’s important to have a tight seal around the edges to prevent any unwanted moisture from entering or escaping the drying chamber.

Heat Source

The heat source in a solar food dehydrator is the sun itself. However, the design of the dehydrator plays a crucial role in capturing and maximizing the use of solar energy. Warm air from the solar collector rises and enters the drying chamber, heating up the air and facilitating an efficient dehydration process.

Vent Covers

Vent covers are necessary for controlling the airflow inside the dehydrator. They facilitate the escape of hot, moist air from the drying chamber, as it is essential to have a continuous flow of warm air so that the food dries effectively. I have to add vent covers at strategic locations to promote optimal air circulation inside the dehydrator.

Drying Racks

Drying racks are where I place the food to be dehydrated. These racks can be constructed from thin wooden slats or wire mesh, which promote air circulation around the food. To enhance the effectiveness of the dehydration process, make sure there is enough space between the racks to allow hot air to circulate freely, ensuring even drying.

Materials and Tools Needed

Plywood

To build a solar dehydrator, you’ll need a plywood sheet as the base for the structure. I recommend opting for exterior-grade plywood since it’s made to withstand weather conditions and will ensure the dehydrator lasts longer. You can purchase plywood at your local hardware store and use a circular saw to cut it to the desired size. Make sure you have enough plywood to create the base, sides, and top frame for the dehydrator.

Aluminum Foil

Aluminum foil is essential in the construction of a solar dehydrator because it serves to reflect sunlight and increase the heat inside the device. You’ll need a sizable piece of foil, preferably heavy-duty aluminum foil, to line the inner surface of the dehydrator’s top frame. This will maximize the sunlight exposure and promote efficient drying of the food items placed inside.

Screen-like Materials

Screen-like materials are necessary for creating trays on which food will be placed for dehydration. These materials allow air to circulate freely around the food while keeping insects and pests out. I suggest using window screens or metal racks as they are durable and easy to clean. Additionally, you can also explore the option of using a cloth screen, provided it is made of food-grade material and allows for proper air circulation.

You’ll need to measure and cut the screen-like materials to fit the dehydrator’s frame. It is advisable to use a staple gun to attach the screens to the plywood structure, ensuring they remain secure during the dehydration process.

Miscellaneous Hardware

Lastly, you will need miscellaneous hardware items to assemble the solar dehydrator successfully. Some of these items include screws to fasten the plywood pieces together, clear glass or polycarbonate to cover the top of the dehydrator, and support brackets to reinforce the structure. An old window can be an excellent alternative for clear glass or polycarbonate, as long as it fits the dehydrator’s dimensions.

Don’t forget to have basic tools like a screwdriver, a measuring tape, and a saw handy during the assembly process. Visiting a hardware store is a great idea to gather all the required materials and tools in one place for a seamless building experience.

Remember to approach the project confidently and follow the necessary steps with precision. With this knowledge and a well-prepared list of materials, you’ll be on your way to creating a functional solar dehydrator to preserve your tasty treats for more extended periods.

Building a Solar Dehydrator

Designing the Solar Dehydrator

I recommend starting by researching various solar dehydrator plans to find a simple and basic design that suits your needs. When designing my own solar food dehydrator, I considered the amount of direct sunlight it would receive and the size of the collector box. The key elements for a successful solar dehydrator are:

- Collector box: A darker section that absorbs sunlight and heats the air.

- Drying chamber: A ventilated area where the food is placed on screens or trays.

- Ventilation system: Allows airflow between the collector box and the drying chamber, facilitating an efficient drying process.

Constructing the Solar Dehydrator

To begin constructing the solar dehydrator, gather the necessary materials, such as plywood, screws, a Plexiglas cover, and insect-proof screening. First, build the collector box using plywood for the bottom and long sides. Opt for a larger collector box if you plan to dehydrate larger quantities of food or need to capture more sunlight. Paint the inside of the box with a dark, matte paint to create that darker section, which will help absorb heat.

Next, build the drying chamber using long pieces of wood to form a frame and attach screens or trays to the frame for the food to sit on. Make sure there is enough space between the trays for air circulation and, if possible, allow for adjustable tray height to accommodate different foods.

Connect the collector box to the drying chamber, ensuring that there is an effective ventilation system in place. This usually involves leaving space at the bottom of the collector box and vents at the top of the drying chamber. The heated air will flow from the collector box through the food in the drying chamber and exit through the vents.

Finishing the Solar Dehydrator

Once the main construction is complete, cover the solar dehydrator with a transparent material such as Plexiglas, which allows sunlight to enter while protecting the food from wind, rain, and dirt. Attach the Plexiglas with hinges, making it easy to open and close when needed. Lastly, secure insect-proof screening over the ventilation system to prevent bugs and critters from entering the dehydrator.

Now that the solar dehydrator is built, position it in a location that receives direct sunlight for the majority of the day. This will ensure optimal drying conditions for your dehydrated goods.

Using a Solar Dehydrator

Dehydrating Different Food Items

I have found that a solar dehydrator is an excellent tool for preserving a variety of food items. It uses the sun’s energy to remove the water content of foods, making them less susceptible to spoilage. Some of the most common items I like to dry using a solar dehydrator are fruits, vegetables, nuts, and meats.

Fruit leathers and beef jerky have become favorites of mine to dry in the solar dehydrator. Fruit leathers are made by pureeing fruits and spreading the mixture evenly on a tray, while beef jerky is dehydrated from thin slices of marinated meat. Using a solar dehydrator, I can quickly turn these fresh foods into tasty, long-lasting treats.

Mastering the Drying Process

The drying process for a solar dehydrator is quite simple. On a sunny day, the dehydrator reaches an optimal temperature for removing moisture from the food. I just need to place the food items on trays inside the dehydrator, and the sun does its work. However, I also keep in mind a few factors that can affect the drying process.

Food thickness: The thicker the food, the longer it will take to dry. So, I try to slice fruits and vegetables evenly to ensure consistent drying.

Humidity: Higher humidity can slow down the drying process. I use additional ventilation and longer drying times on more humid days.

Tray spacing: Proper spacing between trays is essential for good airflow and even drying. I make sure trays are not overcrowded and have enough room between them.

Temperature: Optimal drying occurs between 95°F (35°C) and 145°F (63°C). I monitor the temperature inside the dehydrator throughout the day to ensure optimal results.

In conclusion, using a solar dehydrator, I have been able to preserve a variety of food items while conserving energy and promoting sustainability. By mastering the drying process, I can ensure that my dry produce retains its quality and nutritional value for an extended period.

Advantages of Using a Solar Dehydrator

I believe that using a solar dehydrator is an excellent method for preserving healthy foods. Solar dehydrators harness the power of the sun, making them an eco-friendly and cost-effective alternative to electric dehydrators. In this section, I’d like to share some advantages of using a solar dehydrator.

First, solar dehydrators are energy-efficient and sustainable. Since they rely on solar power, they do not require electricity or fossil fuels. This makes them an environmentally friendly option that contributes to the reduction of carbon emissions. Building a simple solar food dehydrator can be an inexpensive way to start using solar energy in your daily life.

Another advantage is that solar food dehydrator projects are great DIY activities. You can learn how to build your own solar dehydrator from various online tutorials and resources. Not only will this help you save money compared to purchasing an electric dehydrator, but it’s also an enjoyable and educational experience. Building and using a solar dehydrator gives you the opportunity to gain firsthand knowledge about the potential of solar power.

The best part about using solar dehydrators is that they can effectively dry and preserve the nutritional value of your foods. By utilizing the natural heat generated by the sun, solar dehydrators gently remove moisture from your fruits, vegetables, herbs, and other food items without causing significant nutrient loss. Properly dried and stored foods can remain shelf-stable for extended periods, allowing you to enjoy healthy meals and snacks even when fresh produce is not in season.

In conclusion, I’d say that using a solar dehydrator is a convenient, environmentally friendly, and cost-effective way to dry and preserve foods. It not only saves energy but also allows you to explore the potential of solar power and enjoy nutritious, dehydrated foods all year round.

Safety Tips and Reminders

Food Safety

In my experience, ensuring food safety is crucial when using a solar dehydrator. It’s important to remember that bacteria thrive in moist environments, so it’s essential to sufficiently dry the food before storing it. Place the dehydrated food in a clean, dry container and store it in a cool, dry place to prolong its shelf life.

Light and heat can affect the quality of the dried food, so try to store it in a dark location. Another vital aspect of food safety is hygiene. Wash your hands and clean all surfaces, equipment, and containers before and after handling food.

Dehydrator Maintenance

Solar dehydrators need proper maintenance to ensure their effectiveness. I make it a point to inspect and clean the dehydrator regularly to keep it in optimal condition. By removing any debris, dust, or dirt from the trays, vents, and other components, you can maintain the efficiency of the dehydrator.

It’s also essential to check for any damage or wear in the dehydrator’s structure. Repair or replace any broken parts to avoid affecting its performance. Since the dehydrator uses solar energy, regularly inspect and clean the light-catching surfaces to ensure they’re working optimally.

My final suggestion is to track your solar dehydrator’s performance and make adjustments accordingly. This knowledge helps to ensure successful food preservation and a safe experience using the dehydrator.

Remember, the better you take care of your solar dehydrator, the longer it will last and the more effectively it will dry your foods, keeping them safe for consumption.

Additional Resources

I’ve researched various sources and found some valuable information that can help confident DIYers with their solar dehydrator projects. These resources offer step-by-step instructions and additional information for constructing efficient solar dehydrators that can be used for various purposes.

One detailed guide on building a solar food dehydrator can be found on Lucky Belly. This article provides 14 easy homemade solar dehydrator plans to choose from that cater to different needs and preferences. Some of the plans include making a dehydrator from a cardboard box, using household items, or repurposing an old fridge.

Another fantastic resource I found is the Mother Earth News article, which offers a highly tested solar food dehydrator design that can dry 10 pounds of food in just two sunny days. The instructions provided are in-depth and very informative.

If you’re looking for a more community-based project, the Utah State University Extension provides plans for their community solar dehydrator prototype. The plans focus on using food-safe screens and optimal sun exposure for efficient drying of food in local communities.

Lastly, if you’re considering incorporating an electric fan in your solar dehydrator, take a look at the OSU Extension resource. This guide provides solar dehydrator construction plans with various uses of electric fans to assist in air circulation.

These resources offer a great starting point for your DIY solar dehydrator project. With step-by-step instructions and detailed information, I believe they can be valuable for both new and experienced DIY enthusiasts.

Frequently Asked Questions

What materials are needed for a DIY solar dehydrator?

For a basic DIY solar dehydrator, you will need materials such as wooden beams, plywood sheets, vent covers, clear plastic sheeting, and possibly cardboard. You may also need some screws or nails to assemble the various parts. These materials are relatively inexpensive, and a simple solar dehydrator can be constructed for less than $50.

What is the most efficient design for a solar dehydrator?

The most efficient solar dehydrator designs allow for maximum heat and airflow, while also keeping your food protected from pests and weather elements. A popular design is the box-style solar dehydrator, with a separate solar collector to heat the incoming air and shelves or trays inside the box for holding food. The angle and orientation of the dehydrator should be optimized to capture the maximum amount of sunlight throughout the day.

How can I construct a solar powered food dehydrator?

To construct a solar powered food dehydrator, start by building the frame using wooden beams and planks. You can choose the size and dimensions depending on your needs and available materials. Next, create the solar collector using plywood and clear plastic sheeting, which should be angled to capture sunlight efficiently source. Attach the solar collector to the frame, and install vent covers to allow proper airflow. Finally, add shelves or trays inside the box to hold the food while it dehydrates.

What are the best practices for dehydrating food using solar energy?

Before dehydrating food using solar energy, make sure to wash and prepare your food items properly. Cut them into thin and evenly sized pieces, as this will ensure even and faster drying. Spread the food out on trays or shelves without overlapping, allowing air to circulate around each piece. It’s essential to monitor the temperature and humidity inside the dehydrator to achieve the best results, as conditions can vary depending on the weather.

How long does it take to dehydrate food in a solar dehydrator?

The time it takes to dehydrate food in a solar dehydrator can vary depending on factors such as the type of food, thickness of the slices, and even weather conditions. Generally, it can take anywhere between a few hours to a couple of days. Keep in mind that dehydration times tend to increase in cooler or wetter conditions, as the sun’s energy and efficiency of the dehydrator are affected source.

Are there any maintenance tips for solar food dehydrators?

To keep your solar food dehydrator functioning well, it is essential to clean and maintain it regularly. Wipe down the trays and interior surfaces after each use to prevent mold and bacteria growth. Check the solar collector for any wear or damage and replace the plastic sheeting if needed. Periodically inspect the vent covers for blockages and clean them as necessary to ensure proper airflow. Occasionally, you might need to tighten or replace screws and other hardware to maintain the structural integrity of the dehydrator.